2K injection molding process

It doesn't get any more efficient

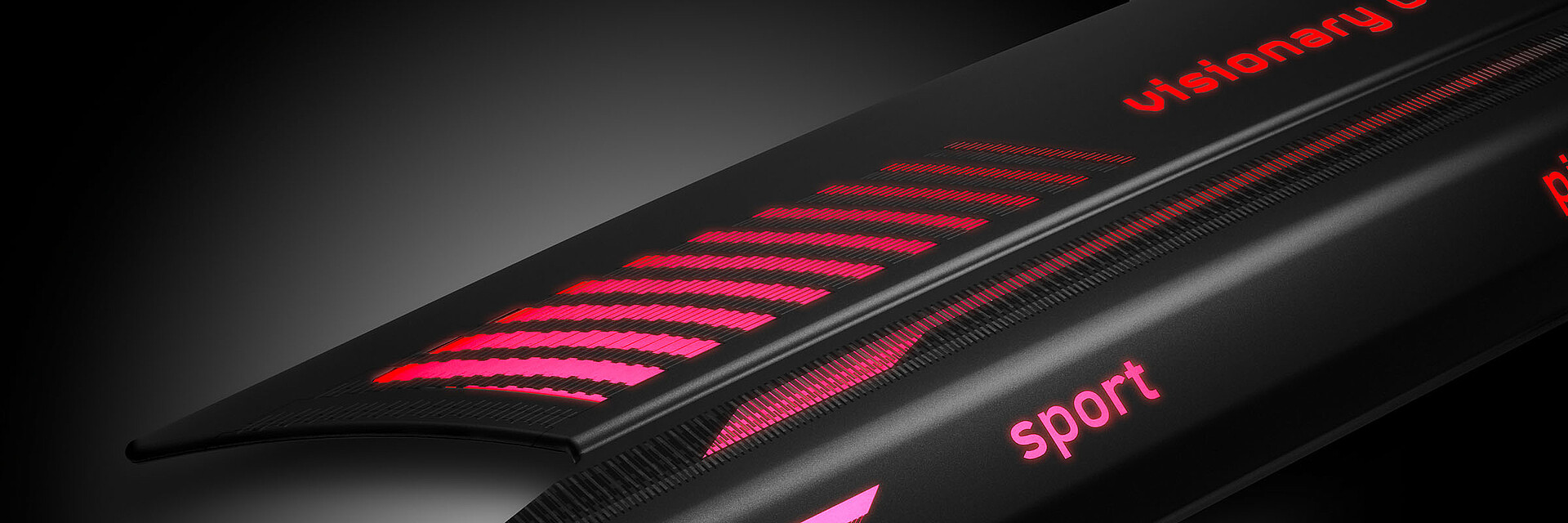

KURZ has developed this world first together with its subsidiary SCHÖFER. SCHÖFER’s Spinstack Mold tool technology is ideal for manufacturing 2K components using the In-Mold Decoration process (IMD). This composition of the materials ABS/PC and the transparent PMMA enables precisely defined backlighting without undesired light diffusion. As a result, both three-dimensional component geometries and structures for 3D light effects and light barriers can be implemented in a single work step. Deformation, contouring, and decoration are all done in one step. Finishing via hot stamping, digital printing, or the integration of touch sensors are also possible. There are solutions for all customer-specific requirements. This is more than 2K plastic injection molding, this is the highly efficient 2K-IMD-process!

Process

Ready-to-use component production

A groundbreaking innovation is the new machine and process technology, which was developed together with the KURZ subsidiary SCHÖFER. The complex technical application is based on SCHÖFER’S high-end tool technology, which is ideally suited to the production of immediately ready-to-install components with large dimensions and enables the use of In-Mold Decoration technology (IMD) in combination with the 2K material mix. This means that both three-dimensional component geometries and structures for 3D light effects and light barriers can be implemented in a single, efficient work step.

The rear-end-cover has a continuous closed surface and large-scale, seamless decoration. It consists of two different translucent plastics. The radar-permeable rear trim supports a wide range of assistance systems, including for autonomous driving. The component can be recycled as a whole and reused as a post-industrial compound.

Advantages at a glance

- Ideal for large components that can be installed directly

- Capable of series production

- Precisely defined backlighting

- Integration of touch functions possible

- Production and decoration in a single step

- Time- and cost-efficient procedure

- Reduces the carbon footprint

- Recyclability of the complete component

- Use of recycled material possible