NFPP

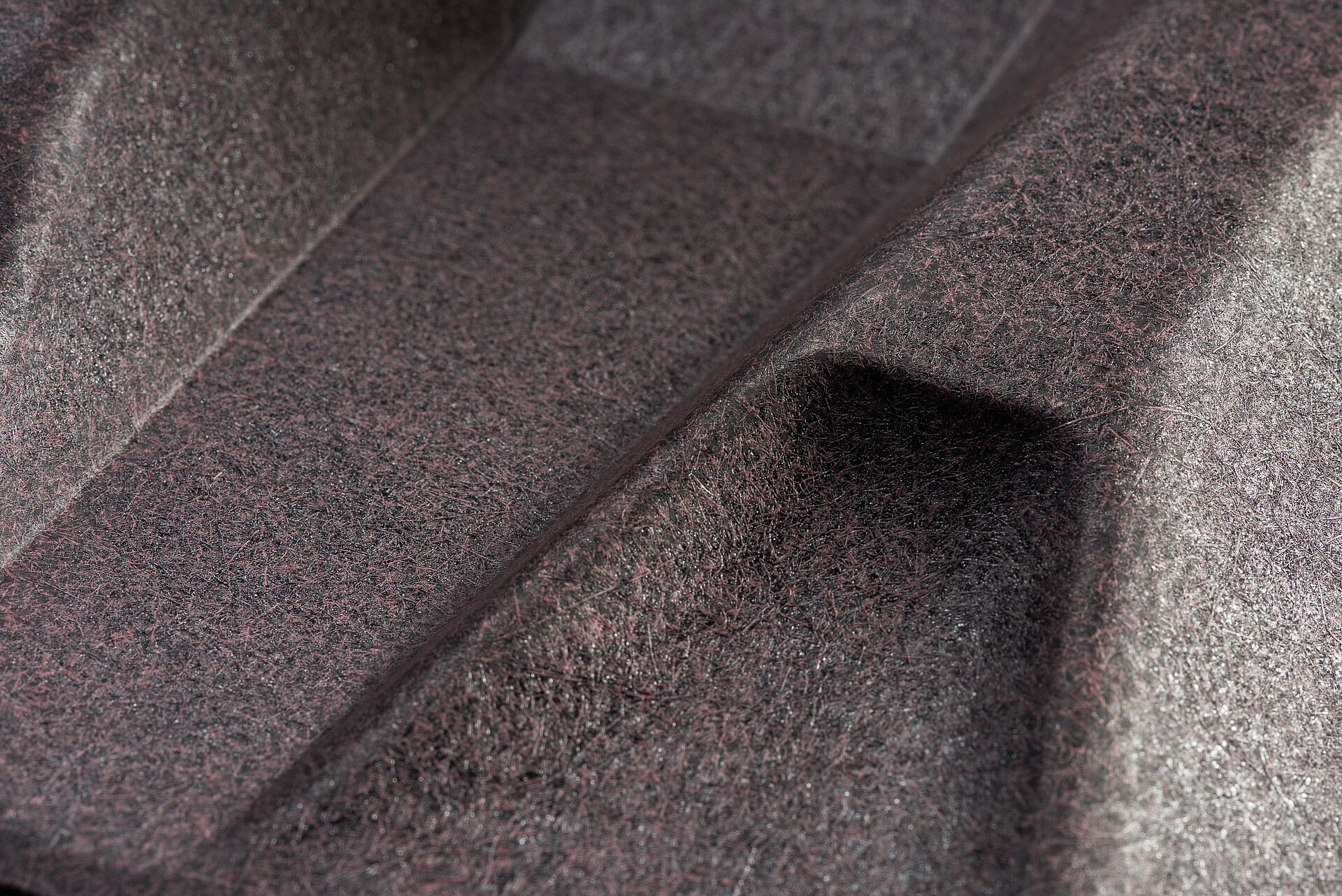

Naturally stylish - natural fibers, a visual and haptical delight

LEONHARD KURZ sets new standards for sustainable interior concepts in the automotive sector

In automotive interior design, smart surfaces, where decoration and functionality merge into one unit, are becoming increasingly important. In cooperation with POLYVLIES and FRIMO and by using the composite material NFPP, LEONHARD KURZ is setting new standards for stylish, ecological vehicle interior concepts.

The challenge

Environmentally conscious mobility is one of the megatrends in the automotive sector. The use of recycled and natural materials in the vehicle interior, in particular, has become an important purchasing factor. The shift in awareness and the changing needs of modern mobility call for innovative solutions that promote the conservative use of resources - while maintaining all necessary standards and quality perceptions for the vehicle interior.

This paradigm shift is causing manufacturers to change their thinking. Materials such as the composite material NFPP (Natural Fiber Polypropylene), which has been used in the automotive sector for years, are taking on a completely new meaning. The material consists of 50 percent natural fibers (e.g., flax or kenaf) and polypropylene fibers. Among other things, it is characterized by low density, good mechanical and insulating properties, and high stability. Whereas NFPP was previously used mostly concealed by leather or textile lamination, the goal now is to visually and haptically highlight the natural appearance of the material and to integrate its natural appearance into the interior design.

The goal

NFPP is used as a nonwoven fabric in mat form. For the intended use in the visible area of the vehicle, a process is required that can be combined with established process technology and does not require any cost-intensive extensions to existing production facilities. This is where KURZ comes in with a new concept. In the first of two steps of the manufacturing process, the decorative layer is applied to the NFPP mat in the form of a PP-based decorative film. The mat is then pressed under pressure and heat and pre-calibrated for later use in terms of wall thickness and elongation. In this way, the PP decorative layer and the PP fiber contained in the mat become malleable and are fused together at the interface. Due to the pressing pressure and compression, the natural fiber is pressed through the interface of the decorative film to the surface and takes on the specified color or design. In the second step, the final shaping and consolidation of the component takes place in a separate mold.

The solution

The new solution from KURZ combines individual decoration with the NFPP fiber to form a matrix that offers designers the greatest possible scope for individual design. This approach emphasizes the material’s natural design language, making the structure of the natural fiber a visual highlight. Flanked by surface modifications in the mold, a wide range of haptic effects can be realized, which preserve the organic structure. In this way, each component takes on unique shapes - depending on the fiber selection and design. Simple single-color designs can be implemented as well as individual decorative elements with patterns, individual images, or multi-color gradations.

Due to the use of PP-based decoration systems, only one type of plastic is used in the overall process. At the same time, NFPP impresses with its mechanical properties and exhibits relatively strong crash behavior relevant for the automotive sector. Due to their low density, components designed with NFPP are also around 25 to 40 percent lighter than pure plastic components. In addition, they offer excellent insulation properties, which leads to energy savings as well as sound optimization in the interior. All in all, this technological approach is a resource-saving alternative to previously used technologies and materials.

So far, NFPP has mainly been used in the automotive industry. However, it can also be used to set targeted accents in other industries - for example, in the furniture industry, especially in the premium and sustainably designed product segment. NFPP thus represents an alternative to conventional materials by combining the advantages of plastics - low weight, malleability, design flexibility, and durability - with the environmental advantages of natural fibers.

Why KURZ is the right technology partner:

- As an expert in innovative surface solutions, KURZ offers a variety of technologies that can be used to finish even demanding products.

- The NFPP solution from KURZ can be combined with other technologies to integrate functional elements and reinforcements in a smart way.

- The new KURZ solution is potentially compatible with existing machines and systems, and it operates entirely without tool wear or an extension of cycle times.

- With this innovation, KURZ is also pursuing a holistic approach to developing solutions along the entire supply chain.

Conclusion

KURZ's innovative concept is suitable as a key technology for natural interior design. It reduces manufacturing costs and also offers the option of easily integrating smart controls in the long term. NFPP decor solutions from KURZ are, therefore, not only an innovative option for environmentally conscious mobility but also a pioneering approach to efficiency and resource conservation in the automotive sector.