DECOPUR®

Crystal clear, radar-permeable, self-healing - surfaces for the mobility of tomorrow: KURZ once again sets standards in the development of components for the automotive industry.

The challenge

Electric vehicles, autonomous driving, networked vehicles, and sustainable mobility - in hardly any other industry is the transformation as omnipresent as in the automotive sector. The pioneering trends require smart solutions and materials that adapt to current requirements, support the latest sensor and camera technologies, and enable future-oriented design.

Especially in the design process for the vehicle exterior, technological advancements are leading to a paradigm shift and establishing entirely new priorities. Front and rear components with electronics and lighting elements, self-healing surfaces, sensor-permeable materials, and increased sustainability demands are setting completely new rules in the automotive industry. Light is becoming increasingly important - after all, it not only functions as a design element but can also be used for communication between road users. This development is clearly reflected in the rising trend towards closed front panels with innovative light integration. A wide range of sensors and camera systems such as radar and LiDAR are, in turn, indispensable for reliable and continuous recording of the surroundings and lay the foundation for autonomous driving. This requires materials that can be penetrated by these systems. Last but not least, the automotive industry is characterized by the need for durable and material-friendly solutions. All of this must be taken into account when developing advanced vehicle concepts and, in particular, when designing surfaces.

The goal

With DECOPUR®, KURZ has developed a decorative finishing technology to provide surfaces for indoor and outdoor use with a durable and aesthetically pleasing coating. This means that components can be finished and given a protective layer in a single step using various decoration processes from KURZ. Polyurethane (PUR) is used for this purpose, which is applied directly to the decorative layer in order to achieve a variety of effects and textures. Polyurethane is known for its self-healing properties - for example in combination with heat - and significantly increases the durability and resistance of surfaces.

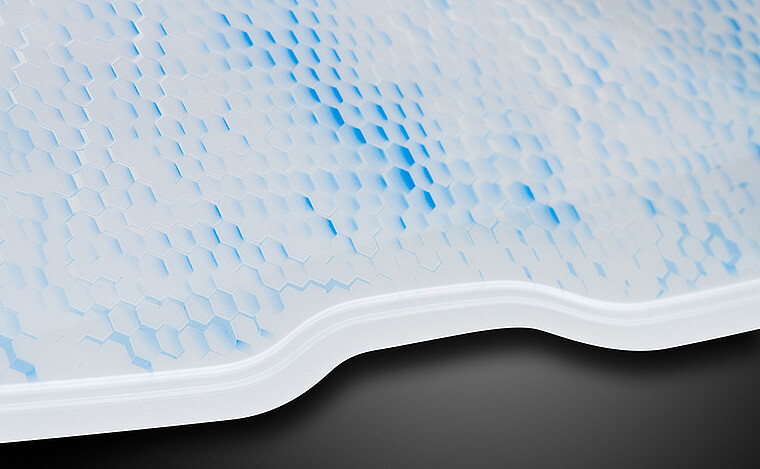

With the help of DECOPUR®, proven KURZ decoration technologies such as In-Mold Decoration (IMD), Hot Stamping, Print Mold Design (PMD), or Insert Molding can be applied with their usual design flexibility and quality, and combined with a high-gloss, crystalline and durable finish. This creates smooth, aerodynamic, and hazard-proof surfaces with impressive depth effects and optional backlighting - perfect for use in industries such as automotive, home appliances, and consumer electronics. Most recently, KURZ has set itself the goal of further developing DECOPUR® and making the technology behind it more efficient and flexible.

The solution

With DECOPUR®, front panels with intricate geometries can be formed in the same machine clamping unit, decorated at the same time, and fully flooded with polyurethane in the next step. All three production steps can be bundled in one machine and the decorative layers can be bonded together extremely firmly thanks to an adhesion-promoting layer specially developed by KURZ, allowing complex product designs with combined functions for autonomous driving to be realized (more details are available here).

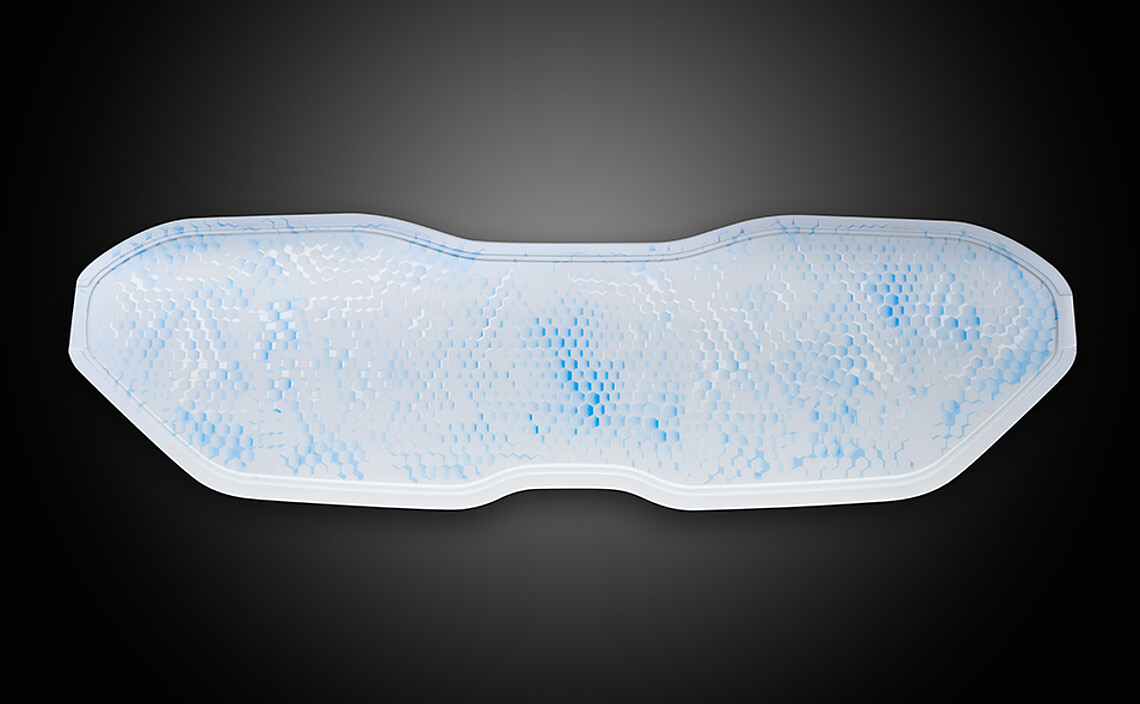

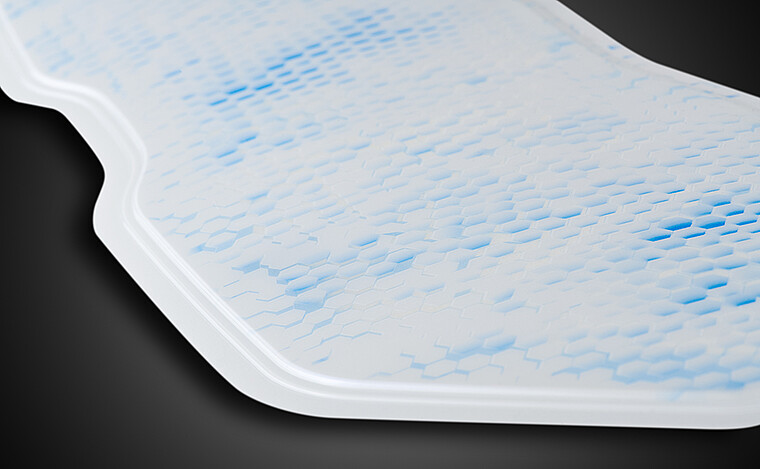

DECOPUR® has been optimized in several ways: In addition to polycarbonate (PC), polypropylene (PP) and other materials can now be used as substrates for injection molding. The choice of material affects production costs, among other things. It has also been possible to significantly reduce the thickness of the PUR coating layer - down to 0.3 millimeters. This leads to considerable material savings. Nevertheless, the surface remains self-healing, radar-permeable, and absolutely versatile in terms of various designs. The colors, lines, patterns, and structures of the decor are protected and effectively staged. In particular, the decoration acquires an unprecedented plasticity and breathtaking depth.

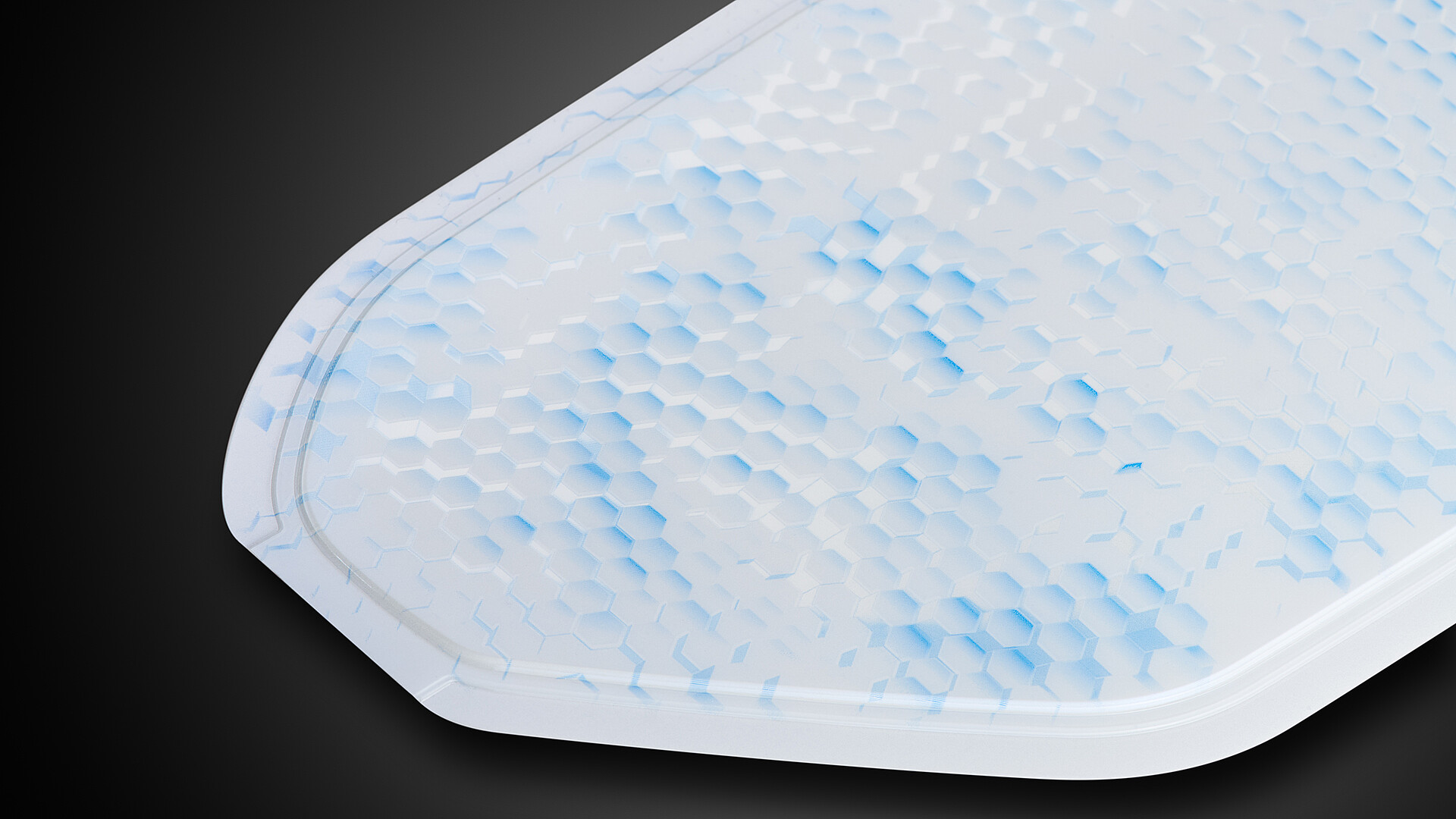

Whether PC, PP, or other thermoplastic plastic materials - DECOPUR® is compatible with the efficient KURZ decoration processes for many substrates. Polypropylene, for example, is especially suitable for the production of large, 3D-formed components in just one process step. In addition, the different substrate variants for the above-mentioned light integration into the surface can be transilluminated. While the transparent PC transmits the light completely, the translucent PP provides light diffusion. The light scattering and the associated degree of transmission can be precisely adjusted using KURZ decoration methods.

Why KURZ is the right technology partner

- KURZ develops and produces unique, smart, and innovative surface solutions.

- Whether it’s an individually designed custom solution or an installation-ready series component - the thin-film specialist realizes product finishes in line with the respective project requirements in each case.

- The focus is always on efficiency and the thoughtful use of natural resources.

- KURZ in 2020 was already awarded the ABC Award in the ‘Future, Mobility, and Parts’ category for its ‘Iconic Space Grille’ front panel concept.

- This first development approach to crystalline designs reinterpreted the classic front grille.

- The efficient DECOPUR® process was already setting new standards in terms of aesthetics at the time - including an exciting prismatic structure under the crystal-clear, smooth surface, and an attractive lighting concept with a day-night design and color changes for communication with other road users.

- Even individual color scenes or light effects to match your favorite music were conveyed to the outside by the exterior panel.

Conclusion

The DECOPUR® technology has been significantly further developed by increasing the range of possible substrates, on the one hand. On the other hand, KURZ has succeeded in significantly reducing material consumption, which also has an impact on production costs. DECOPUR® is, therefore, not only a production-ready solution from KURZ for the mobility of tomorrow but also the next step towards even more efficient and economical technologies for automotive construction. With DECOPUR®, manufacturers and suppliers can come up with complex product designs with combined functions for electric mobility, connected vehicles, and autonomous driving.