RIM Design

A design revolution for wheels

Rims offer a previously unheard of opportunity to customize the exterior. Together with industry experts, KURZ develops solutions that make rims a unique eye-catcher on every vehicle. Benefit from unprecedented design options that can give your brand a decisive competitive edge. Turn wheels into statements with the Hot Stamping PERFORMANCE+ process.

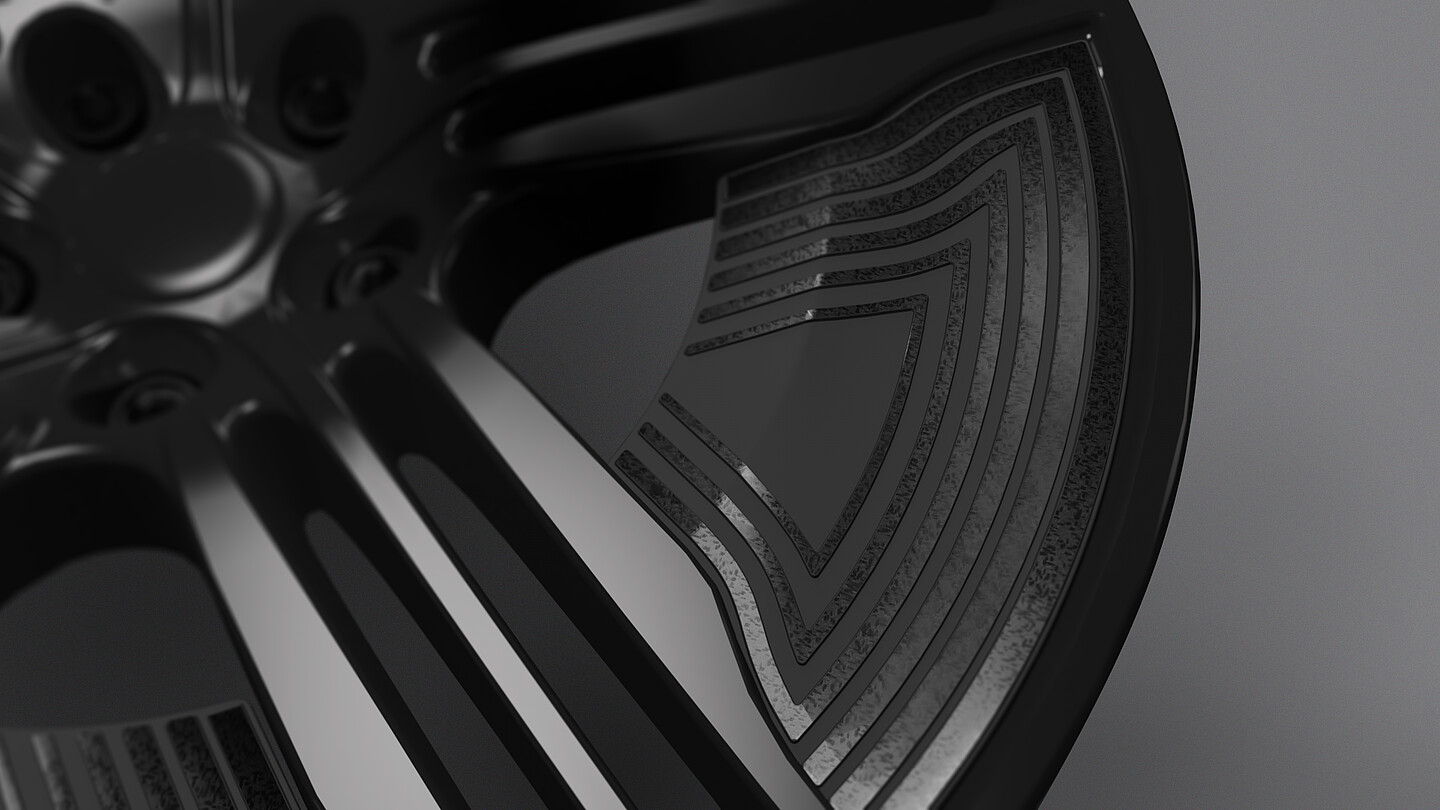

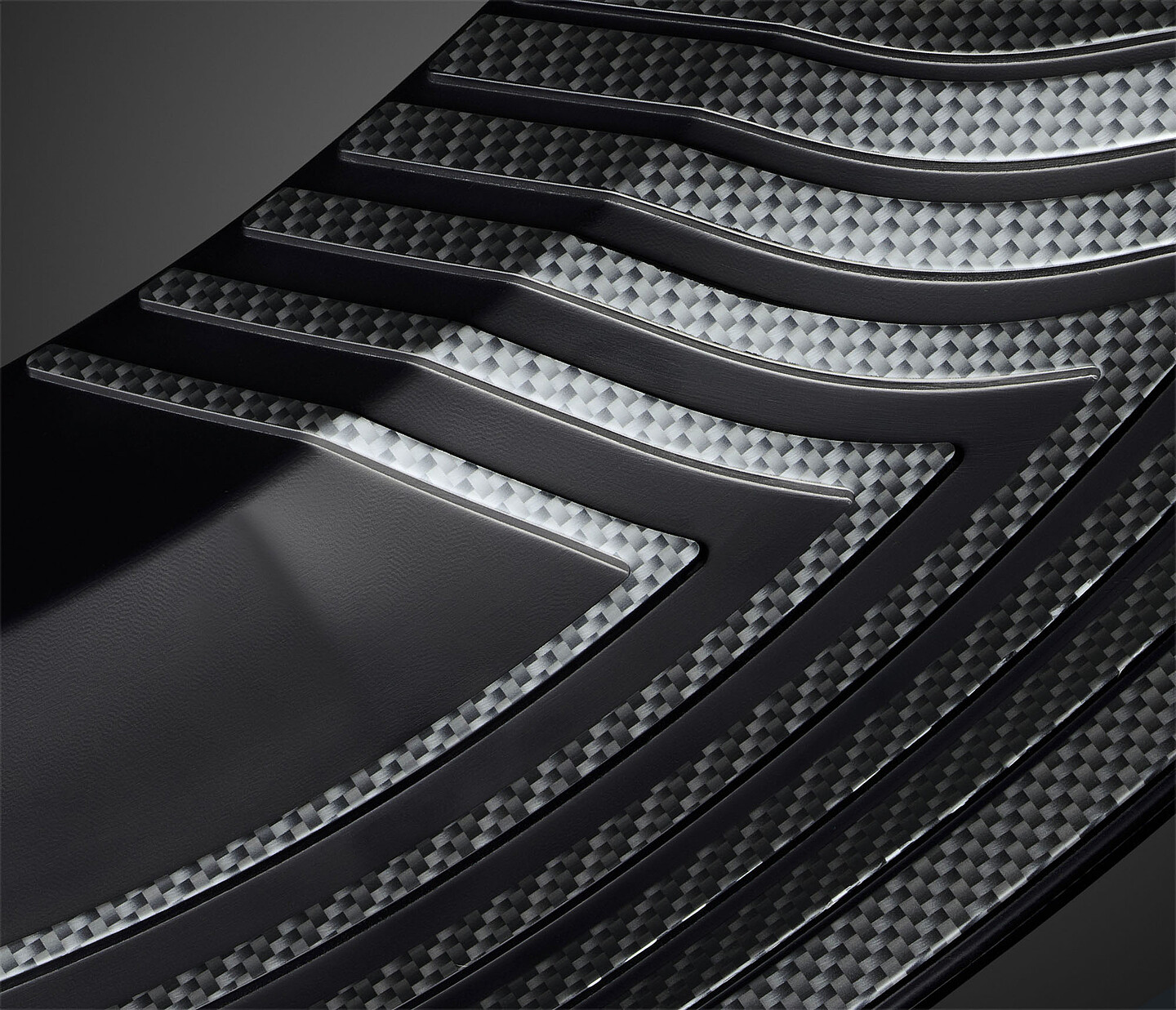

Precision down to the smallest detail: Rim inserts with holographic carbon design

Organically shaped rim inserts decorated using the PERFORMANCE+ hot-stamping process were created in cooperation with the wheel manufacturer RONAL GROUP. The holographic carbon design is the perfect complement to the wheel design of the future. New light effects and reflections are created, especially in motion. What’s more, the inserts reduce air resistance, thus increasing the range of electric vehicles and lowering the noise level when driving. The production-ready decoration process is also suitable for the use of recycled materials.

Hot stamping on aluminum rims

KURZ and RONAL GROUP revolutionize rim decoration: Hot Stamping PERFORMANCE+ is used to directly and efficiently finish aluminum wheels. Without additional work steps such as electroplating, metallic color gradients, intricate color accents, or impressive hologram effects are created and set new design standards.

Project partner

Your advantages at a glance:

- Innovative design element also for use in the aftermarket

- Unique decoration for wheels and inlays thanks to the patented Hot Stamping PERFORMANCE+ process

- Series-ready, efficient process reduces CO2 emissions and ensures a low reject rate

- Thin-film decoration is thinner than a human hair and thus ensures recyclable components

- Also suitable for recycled materials

KURZ as a solution partner

We strive for close collaboration with our customers along the entire value chain. That’s why we are constantly further developing our processes. For example, the optimized Hot Stamping PERFORMANCE+ process can now also be used to economically decorate 3D geometries with a lower carbon footprint - in series production.