Future-proof decoration processes and surface technology for individual designs

help to expand the market position. It is convincing and inspiring when appearance, design, and technology work together perfectly. Efficient total solutions that make the ecological footprint as small as possible.

Part Advisor design check

Perfect design starts with product development. Use the KURZ Part Advisor and find the most efficient and sustainable solution in just a few steps, together with our experts.

Unlimited decoration possibilities

Decoration processes

Hot stampingFlexible, with maximum precisionDecoration and sustainable metallization of surfaces, full-surface or partial

Hot stampingFlexible, with maximum precisionDecoration and sustainable metallization of surfaces, full-surface or partial IMD In-Mold DecorationDecoration and production in a single stepFor individual surfaces with unique and sustainable designs that feel fantastic

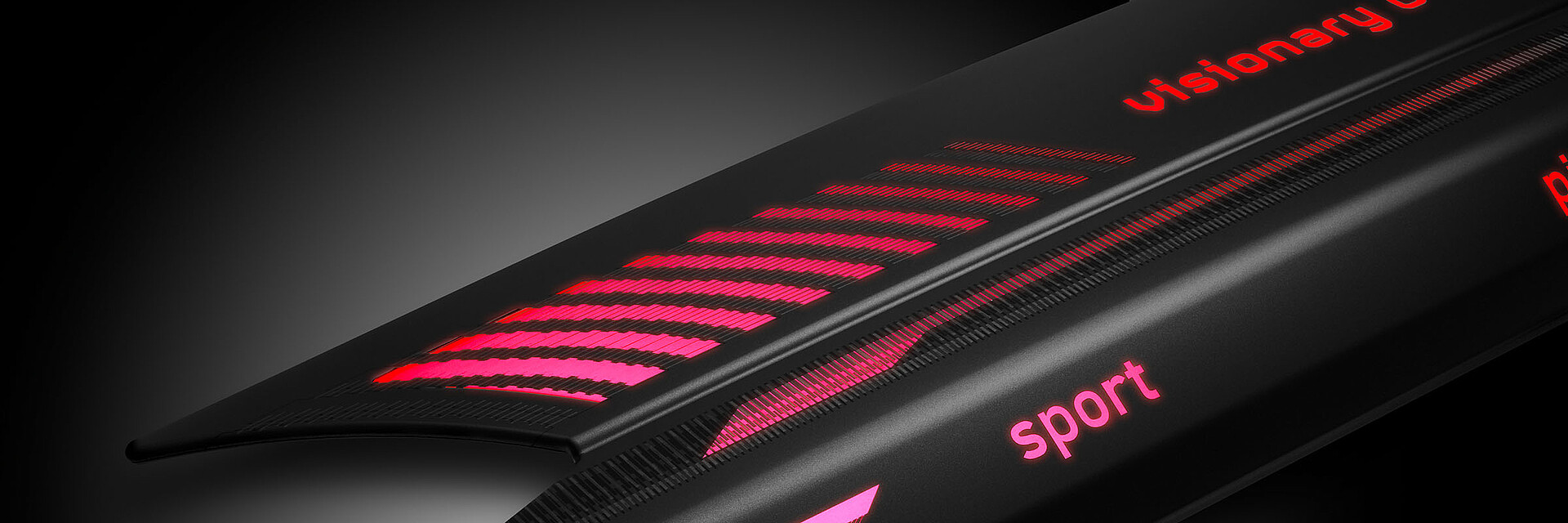

IMD In-Mold DecorationDecoration and production in a single stepFor individual surfaces with unique and sustainable designs that feel fantastic 2K IMD process2 plastics, one processIdeal for the production of large components using the IMD process with precisely defined backlighting. Developed jointly with KURZ subsidiary SCHÖFER

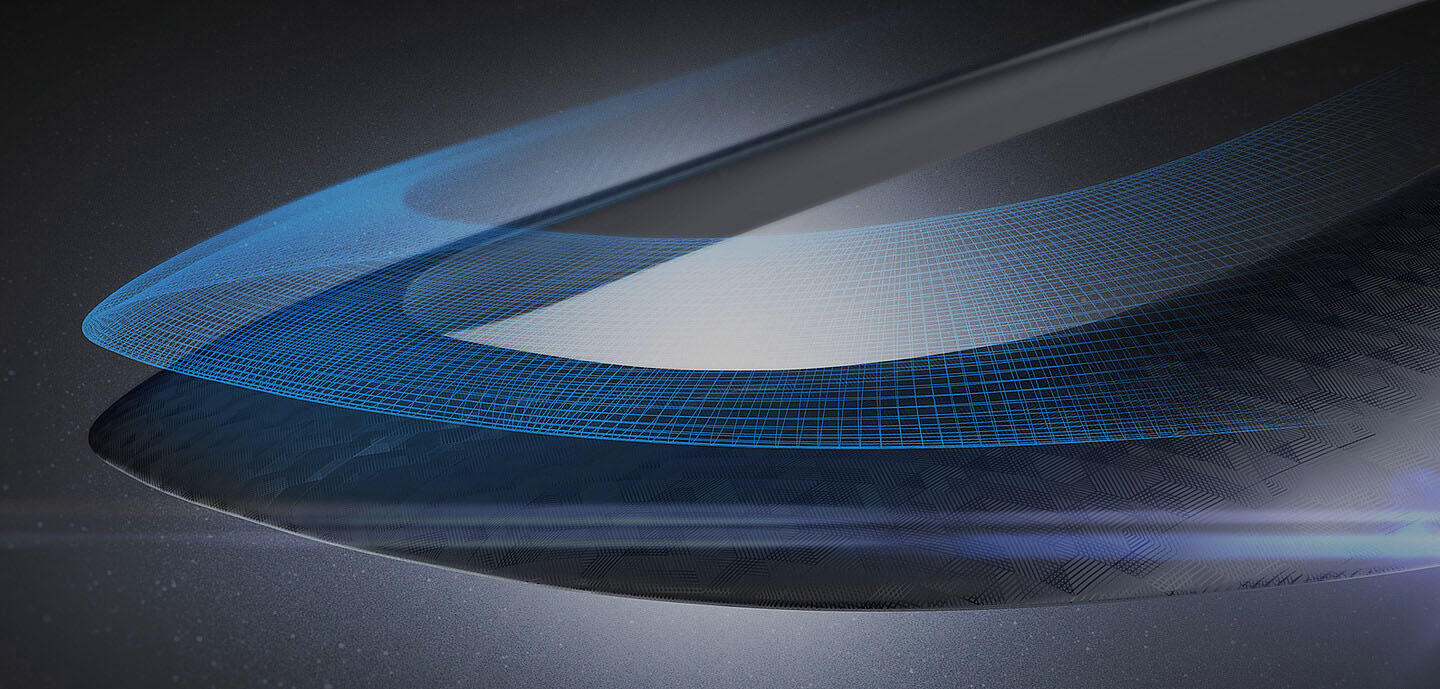

2K IMD process2 plastics, one processIdeal for the production of large components using the IMD process with precisely defined backlighting. Developed jointly with KURZ subsidiary SCHÖFER IMD VARIOFORM®3D surface decorationEfficient decoration of complex 3D components - perfect for small series and custom designs

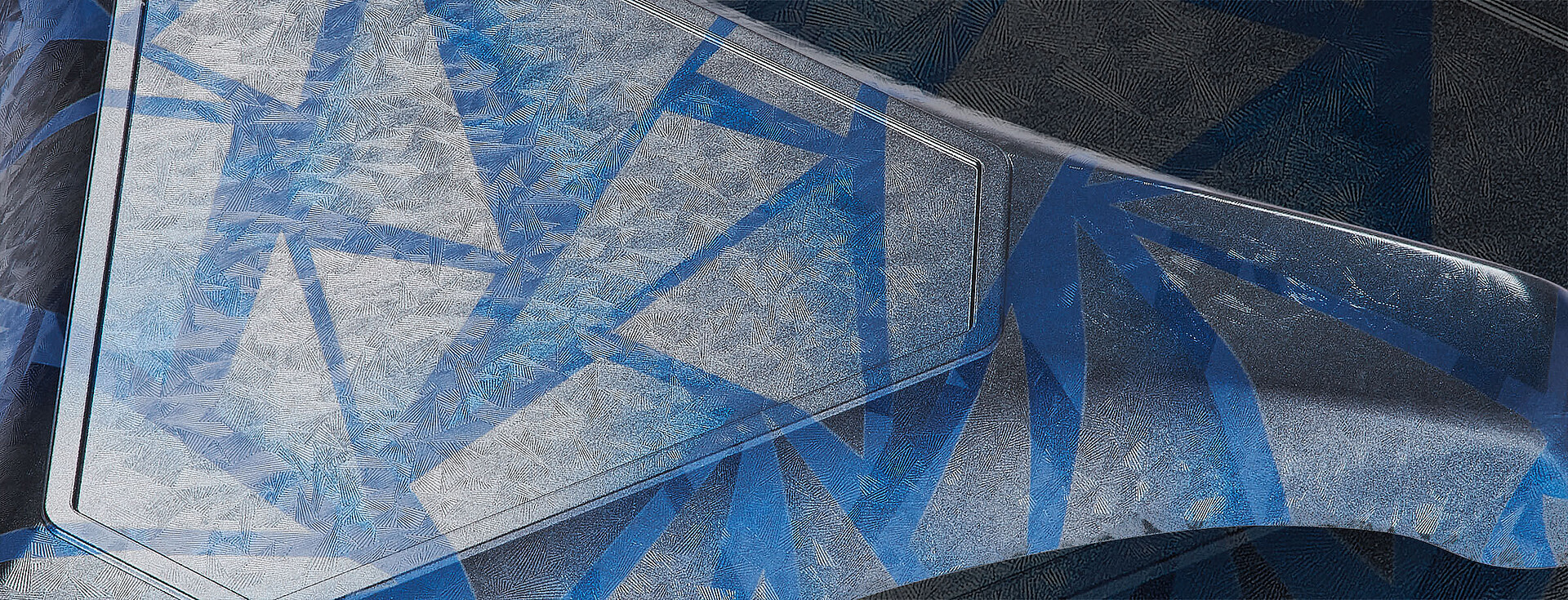

IMD VARIOFORM®3D surface decorationEfficient decoration of complex 3D components - perfect for small series and custom designs IMD UNIFYIndividualization by digital printingCustomization with series advantage down to a quantity of 1. Suitable for special editions or for special requirements

IMD UNIFYIndividualization by digital printingCustomization with series advantage down to a quantity of 1. Suitable for special editions or for special requirements DECOPUR®Self-healing surfacesPUR-flooded, self-healing design surfaces for fascinating depth effects and top performance

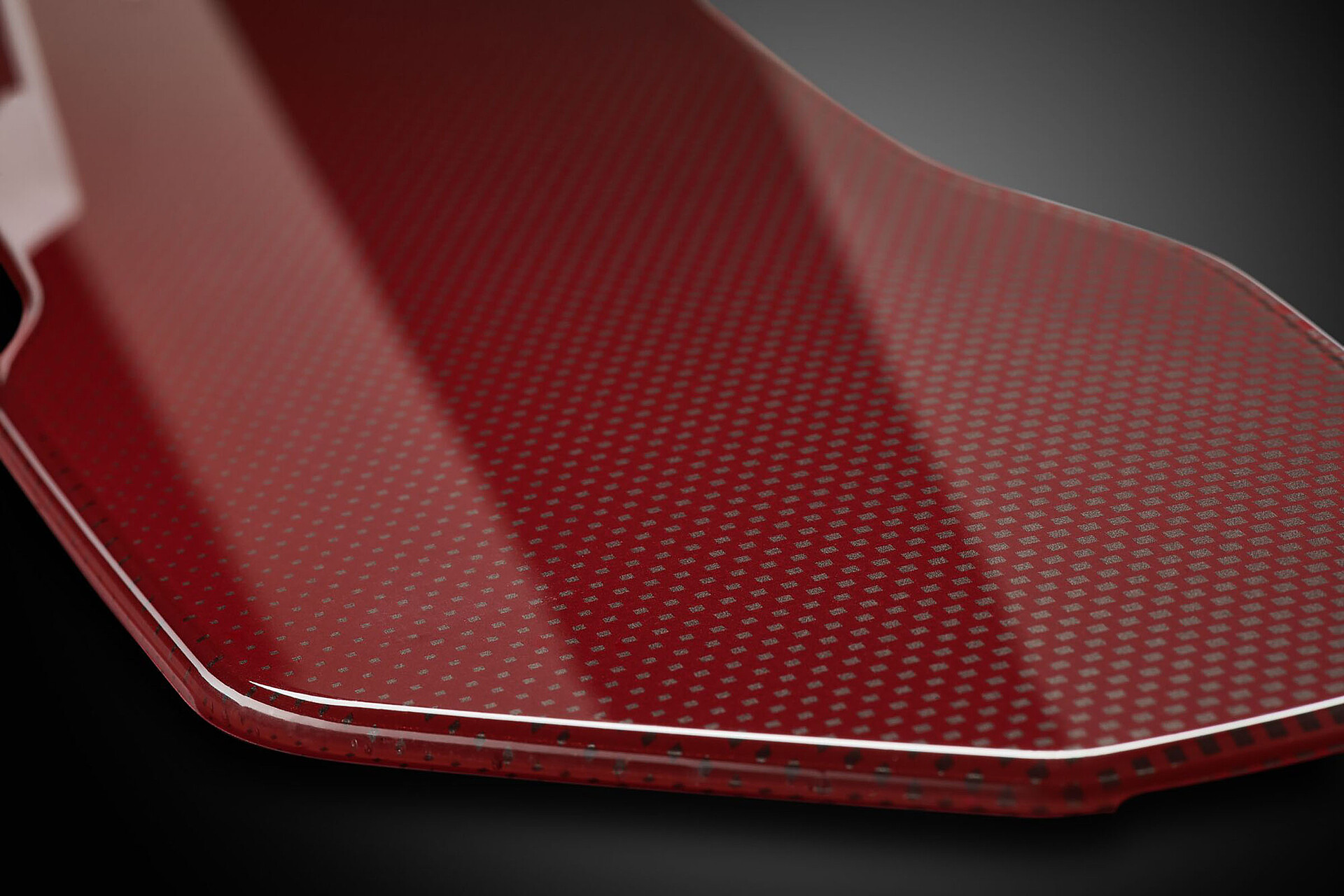

DECOPUR®Self-healing surfacesPUR-flooded, self-healing design surfaces for fascinating depth effects and top performance Insert MoldingFor complex geometriesHot stamping, deep drawing, and injection molding for the decoration of heavily shaped components

Insert MoldingFor complex geometriesHot stamping, deep drawing, and injection molding for the decoration of heavily shaped components NFPP DecorationEspecially for natural fiber compositesEfficient and sustainable decoration highlights the uniqueness of the material beautifully

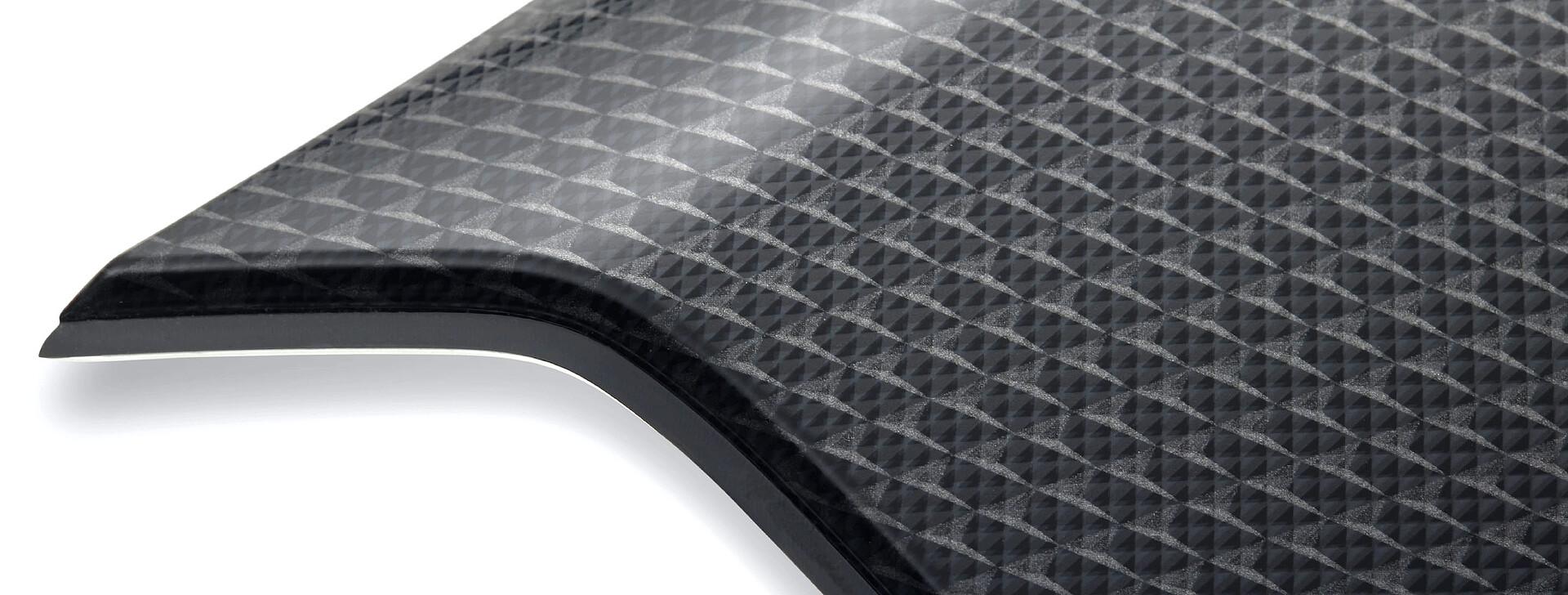

NFPP DecorationEspecially for natural fiber compositesEfficient and sustainable decoration highlights the uniqueness of the material beautifully PMD Print-Mold DesignSpecial screen printing technologySpecial silk-screen printing technology for spectacular interior designs with depth effect and feel

PMD Print-Mold DesignSpecial screen printing technologySpecial silk-screen printing technology for spectacular interior designs with depth effect and feel

Sensor integration

FFB Functional Foil BondingSubsequent sensor integrationPrecise sensor integration even for complex shapes directly after the injection molding process.

FFB Functional Foil BondingSubsequent sensor integrationPrecise sensor integration even for complex shapes directly after the injection molding process. IME In-Mold ElectronicsSimultaneous sensor integrationDecoration and sensor integration take place in one process step. For a shorter value chain and reduced energy consumption.

IME In-Mold ElectronicsSimultaneous sensor integrationDecoration and sensor integration take place in one process step. For a shorter value chain and reduced energy consumption.

Machines and tools

For optimum production results, everything has to be right: space utilisation, the right equipment, perfect integration into the production process. We support you in perfectly harmonising decoration, machine and stamp.