The Challenge

An increasing number of smart control elements with Human machine Interface (HMI) defines the market. Customers' product requirements in terms of attractiveness and convenience are constantly increasing. How can plastic manufacturers balance design requirements, cost and process efficiency, and sustainability?

The Goal

In order to be able to implement innovations cost-effectively, the manufacturing process must be optimally coordinated with the product. Excellent designs with intelligent features are a clear competitive advantage. Producers want a process solution that lets them not only refine their complex plastic components reliably, quickly, and gently, but also easily equip them with smart features such as touch control.

The Solution

In order to meet current market requirements, LEONHARD KURZ developed a completely new technology together with its partners POLYIC, WITTMANN BATTENFELD, and Georg Kaufmann Formenbau AG: IMD VARIOFORM®. The formula for the success of this process lies in the bundling of four otherwise independent production steps: Decorating, thermoforming, injection molding, and punching.

For this purpose, a foil feed device specially developed for plastic finishing is used, which guides the decorative laminate foil to the tool. During the transport process, the finishing layer is heated via infrared and is thus malleable before it is introduced into the tool via a vacuum system. At the same time, a 3D-deformed sensor is inserted on the opposite side of the tool. After closing the tool, the injection of a thermoplastic melt follows.

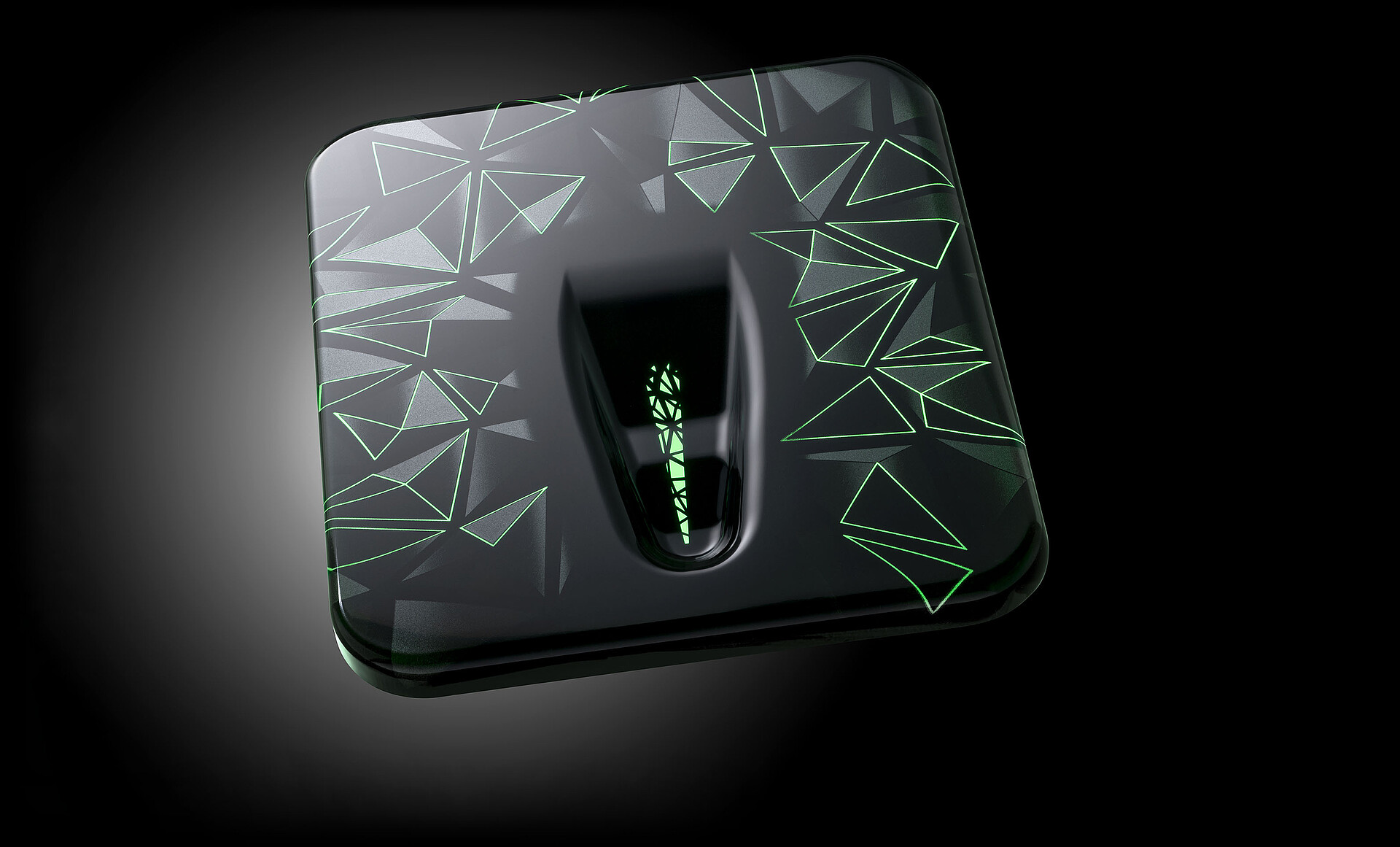

The result is an attractive plastic component that is equipped with a complete single-image decoration on the front and a capacitive touch sensor on the back, in just one process. IMD VARIOFORM® thus combines high shape and design flexibility with high resource efficiency. Another advantage of the process is the possible use of recycled plastic materials and the unrestricted recyclability of the decorated component.

WITTMANN BATTENFELD – The Specialist for Injection Molding Systems

Machine manufacturer WITTMANN BATTENFELD has developed an injection molding system specifically for the IMD VARIOFORM® process, which bundles decoration, thermoforming, injection molding, and punching. To this end, the company also supplied all peripheral components in order to ensure optimum component tuning.

Georg Kaufmann Formenbau AG – Custom Injection Molding Tools

Known for its innovative and custom injection molding tools, Georg Kaufmann Formenbau AG supported the project with its patented In-Mold Wrapping (IMW) bending and trimming system. The integrated tool technology makes it possible to finalize the plastic component during the injection molding process.

POLYIC - innovative sensor technology

POLYIC developed the wafer-thin, formable sensors for the functional integration and desired design freedom for 3D-shaped components and curved surfaces.

Why KURZ Is Your Ideal Technology Partner

- IMD VARIOFORM® – as a one-stop process – enables highly flexible, individual plastic finishing in series production

- KURZ as an all-round solution provider with expertise in the areas of design, mechanical engineering, and sensor technology

- Comprehensive network with highly qualified partners from the plastics industry

- Wide range of applications – from automobiles and household appliances to consumer electronics

- Increased sustainability thanks to resource conservation, energy efficiency, and possible use of recycled materials

The Conclusion

KURZ’s partnership network in the field of plastic decoration enabled the development of an innovative manufacturing and decoration process with high process efficiency. The development of IMD VARIOFORM® was only made possible by combining POLYIC sensor technology with the know-how of the machine specialist WITTMANN BATTENFELD and the tool technology of Georg Kaufmann Formenbau AG.

With our innovative process, you can reduce costs, material, and energy use in just one step, while remaining highly flexible in form and design. Even complex component concepts with touch functionality for HMI applications can be realized in top quality. This is how you can secure your competitive advantage in the long term!