SPE Automotive Award 2024

Award for front design and rear end cover

This year, two exterior concepts from KURZ were honored at the SPE Automotive Award: The integrated front panel and the rear end cover, which has already won several awards. The prestigious award is presented by the International Society for Plastics Engineering SPE Central Europe every one and a half years for the most innovative concepts and developments. An independent jury of experts evaluates the submissions according to the standards of the automotive and plastics industries.

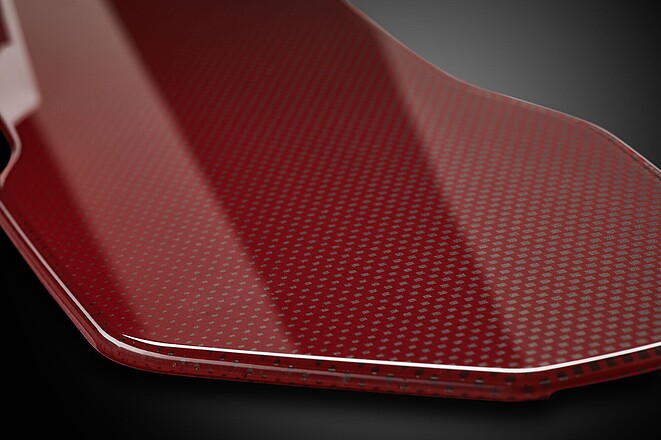

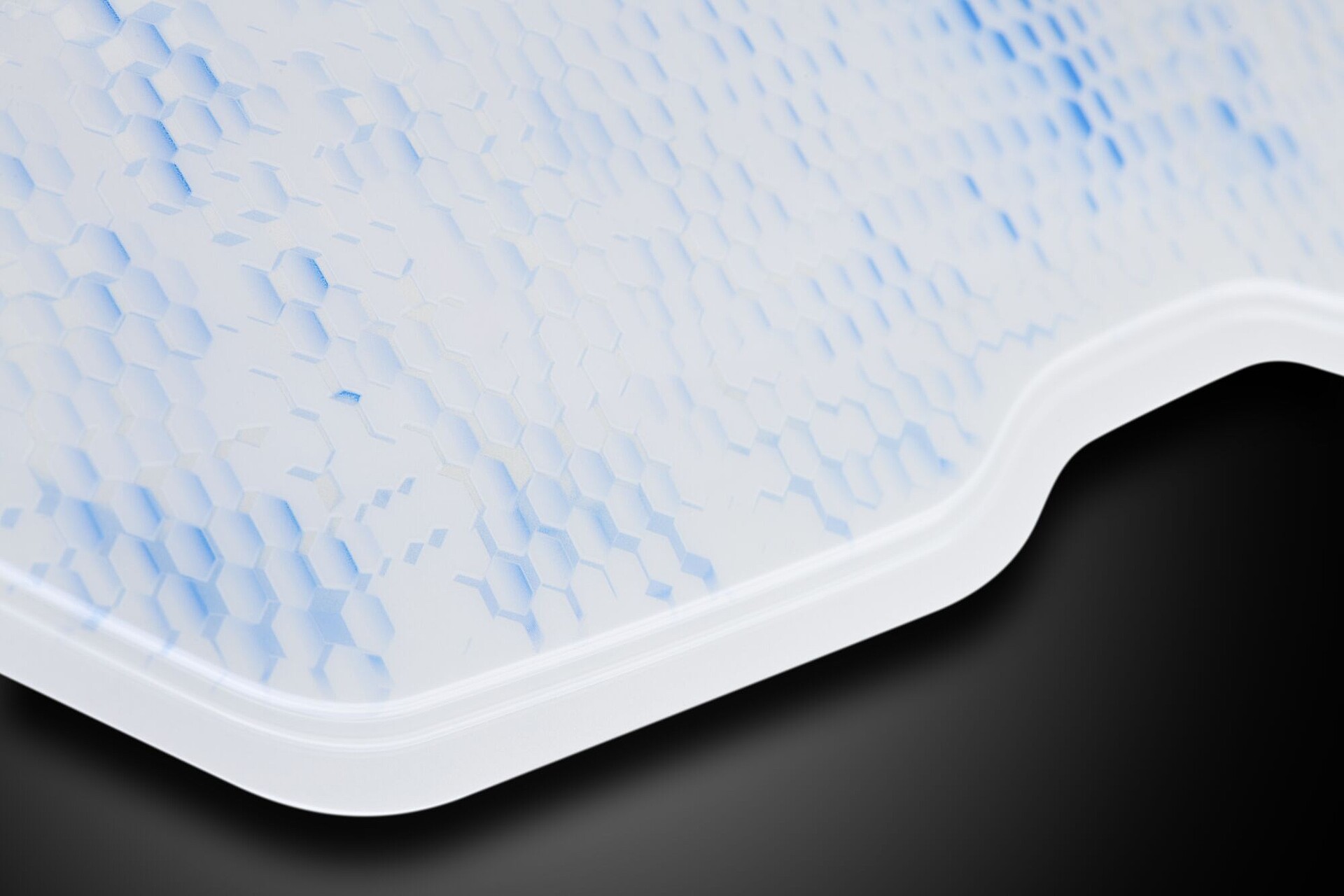

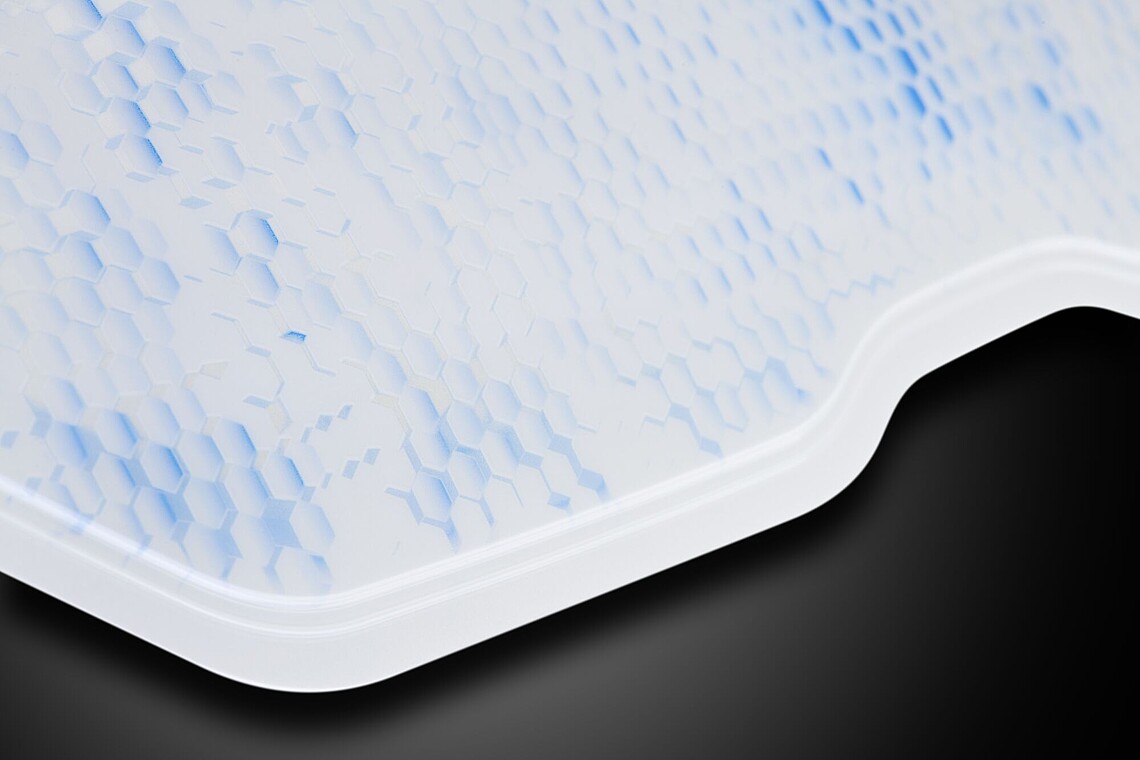

Front panel with DECOPUR®

The pioneering front panel took fourth place in the ‘Enabler Technology/Materials & Technologies’ category. Several specialists pooled their expertise for this component. The process technology and design come from KURZ, the material (translucent polypropylene) from raw material manufacturer SABIC, the tools from KURZ subsidiary Schöfer and the machine from Engel Austria.

Requirement

New drive technologies are revolutionizing the design rules for vehicle design - especially at the front. High functionality and brand-defining design dominate here. As front modules are carriers of highly complex technology, they have to be very robust. In addition, durable materials and efficient processes are required to make the vehicles of tomorrow more environmentally friendly in production and operation.

DECOPUR® is the answer to these industry challenges. This is a technology developed by KURZ that enables the production and decoration of the front panel and its coating with polyurethane (PUR) in a single process and machine. The technology has now been made even more flexible and efficient: On the one hand, the range of possible substrates has been increased and, on the other, KURZ has succeeded in significantly reducing the amount of PUR material used.

Solution

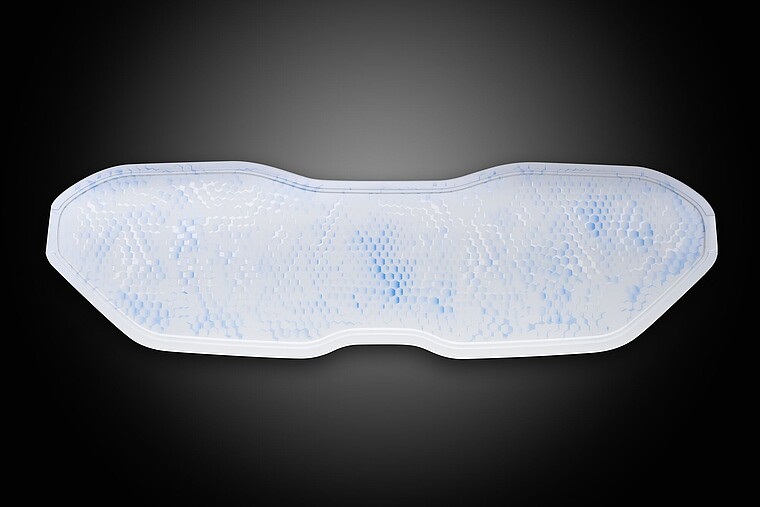

DECOPUR® makes it possible to form components with complex geometries in the same machine clamping unit, decorate them at the same time and seamlessly flood them with polyurethane in the next step. The PUR coating of the excellent front panel is extremely thin at just 0.3mm and at the same time extremely stable. It has self-healing properties and makes the component surface weather-resistant and durable. It also creates breathtaking gloss and depth effects and brings out the design of the front panel to fantastic effect.

By using less material and bundling several process steps into one compact process, manufacturers benefit in several ways: They need less energy, save space in the production line and reduce their production costs.

This convinced the jury

- Highly efficient process that bundles several process steps

- Extremely low material usage for decoration and flooding with PUR

- Weather-resistant, durable and self-healing surface

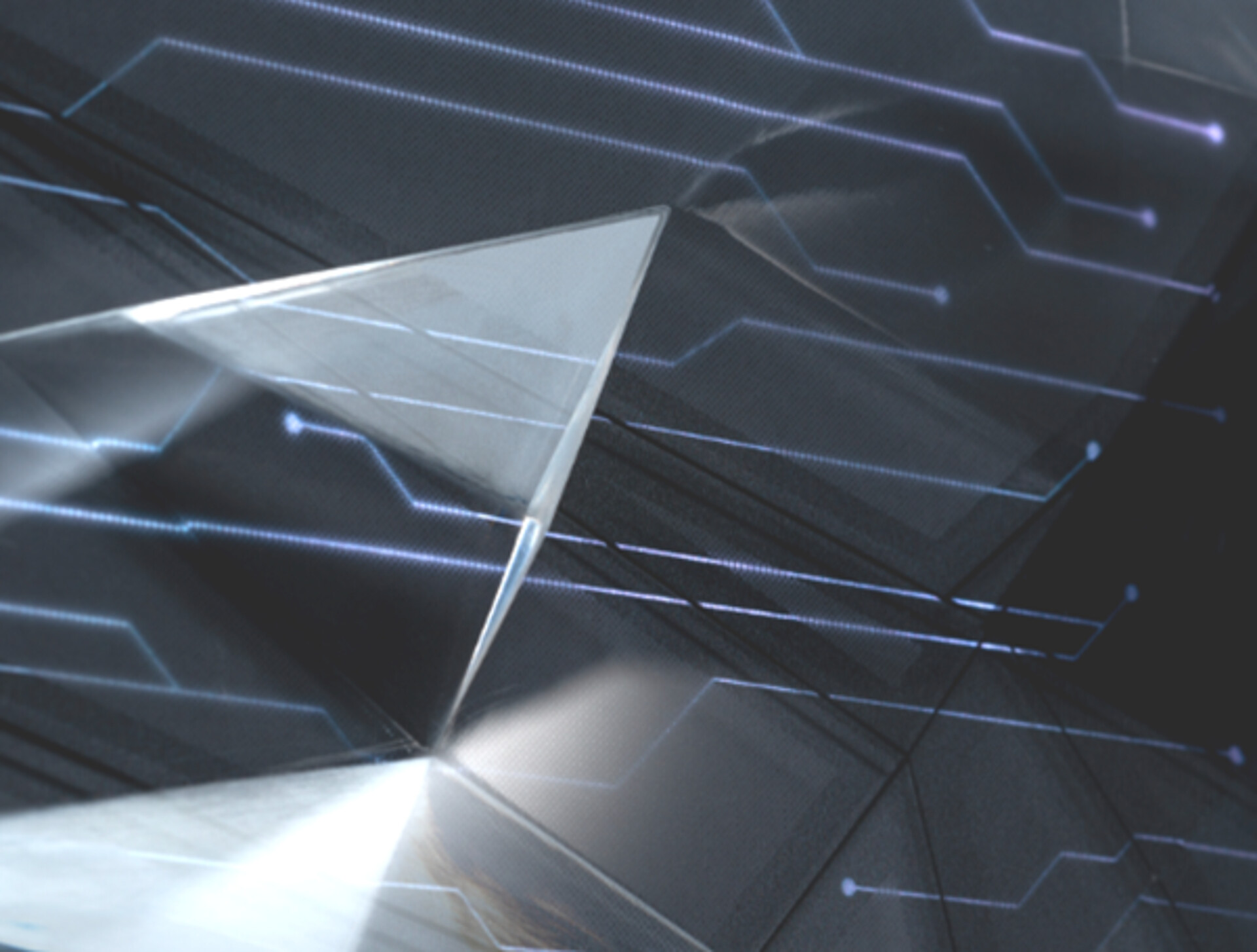

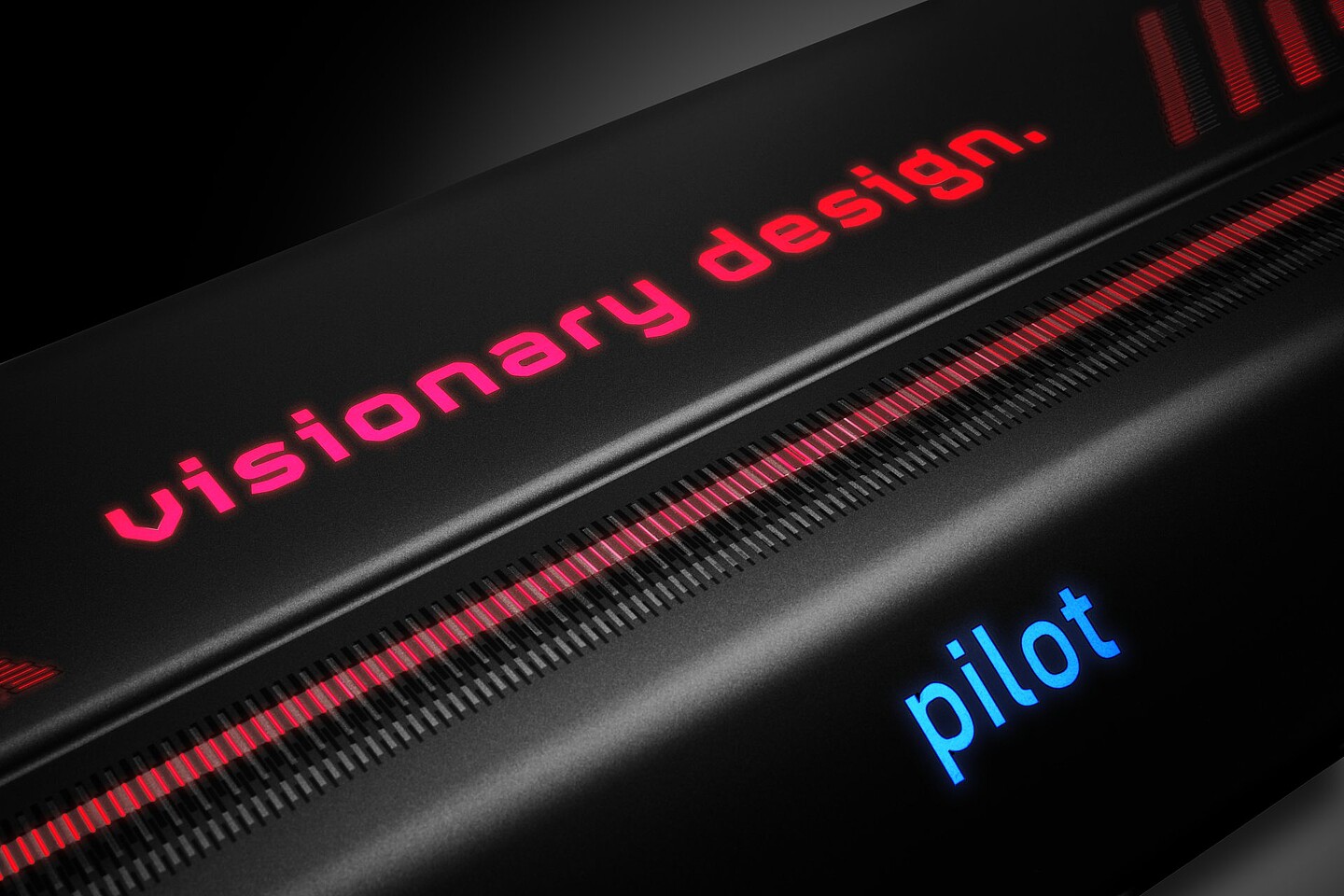

- Impressive design variety with depth effects and optional backlighting

Project partners

Honorable mention for

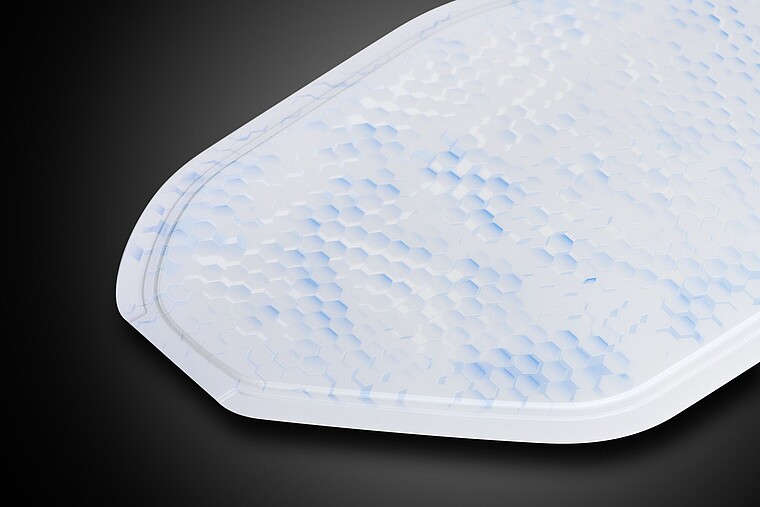

Rear End Cover

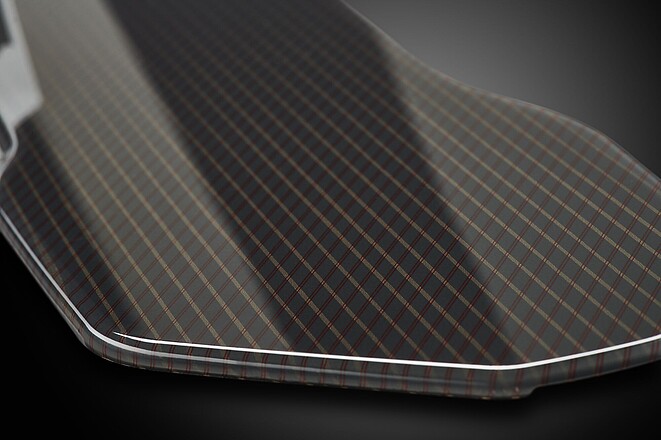

The rear component, which has already won several awards, also impressed the SPE Award jury. It was honored with the Nomination Award in the ‘Enabler Technology/Part & Component Design’ category.

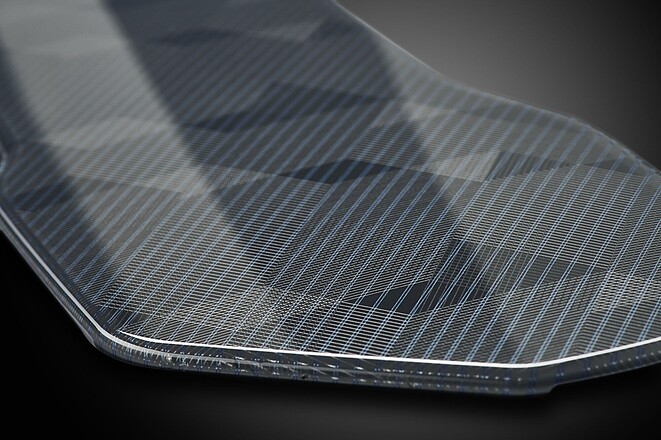

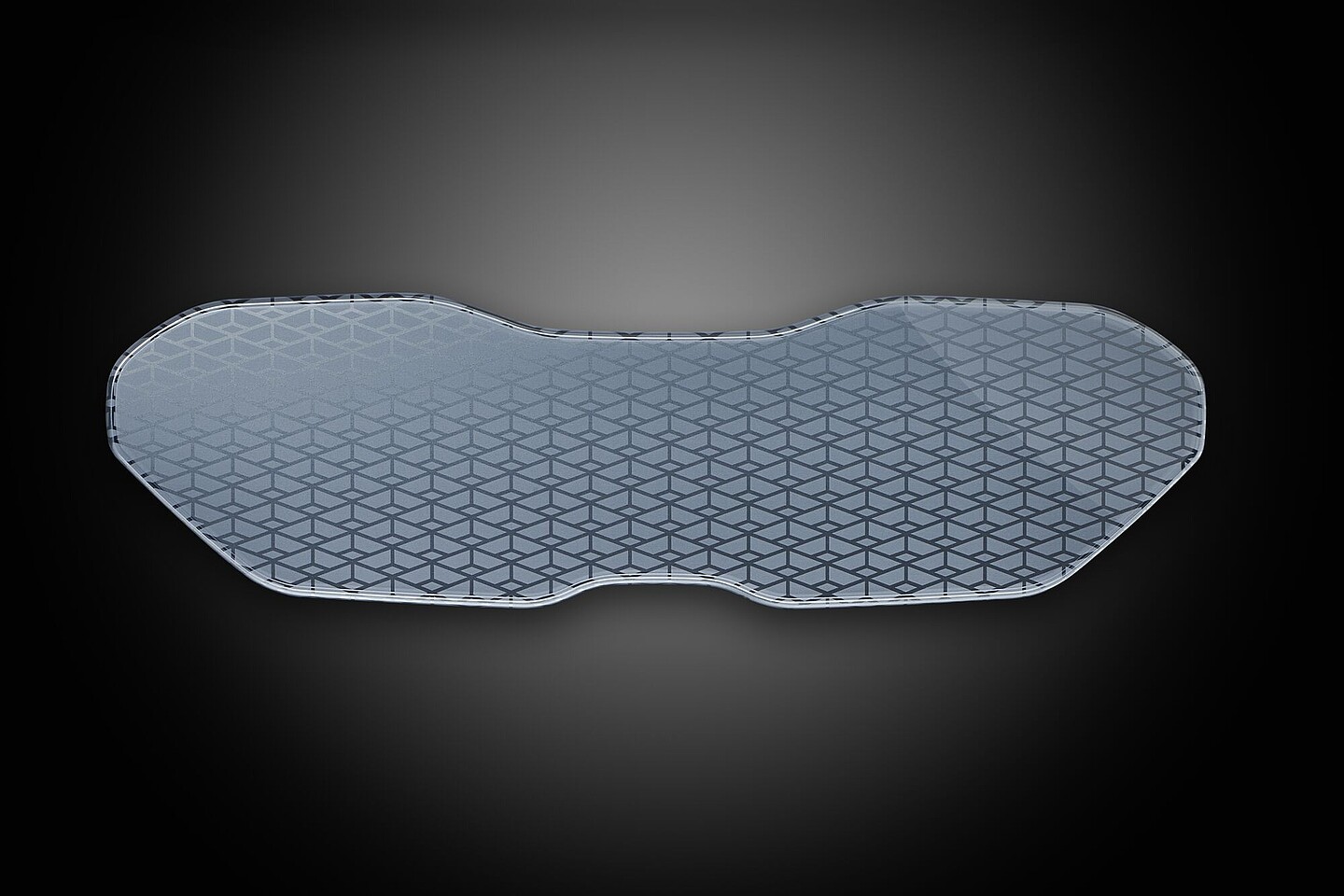

This revolutionary design for the mobility of the future consists of a multi-component structure suitable for series production. It is produced in the highly efficient 2K-IMD process. The rear end cover comes out of the machine in just 60 to 70 seconds and can be used immediately. Thanks to the special 2K material mix of two different types of plastic - opaque and transparent - the component impresses with fascinating 3D light effects with targeted light shielding, color gradients and day-night designs.

The completely closed surface impresses with its large, seamless decoration. Wafer-thin sensor foils attached to the back enable the integration of convenient touch operation. Shy tech design only makes smart touch functions visible when they are activated. The innovative concept is rounded off by its radar-transparent and 5G-capable metallization, which enables car-to-x communication and paves the way for autonomous driving.

The component can be recycled as a whole and the recyclate can be reused as a post-industrial compound.