Touch Control & sensor technology

Touchscreens are already standard on many home appliances, vehicles, and communication devices. A light tap, swipe, or finger-circle – and functions are set in motion. In collaboration with its high-tech partner POLYIC, KURZ offers flexible sensor technology and state-of-the-art design, perfectly tailored to your needs. You’ll benefit from customized and ready-to-use sensors to suit your integration methods. Functional, durable, and ready for series production.

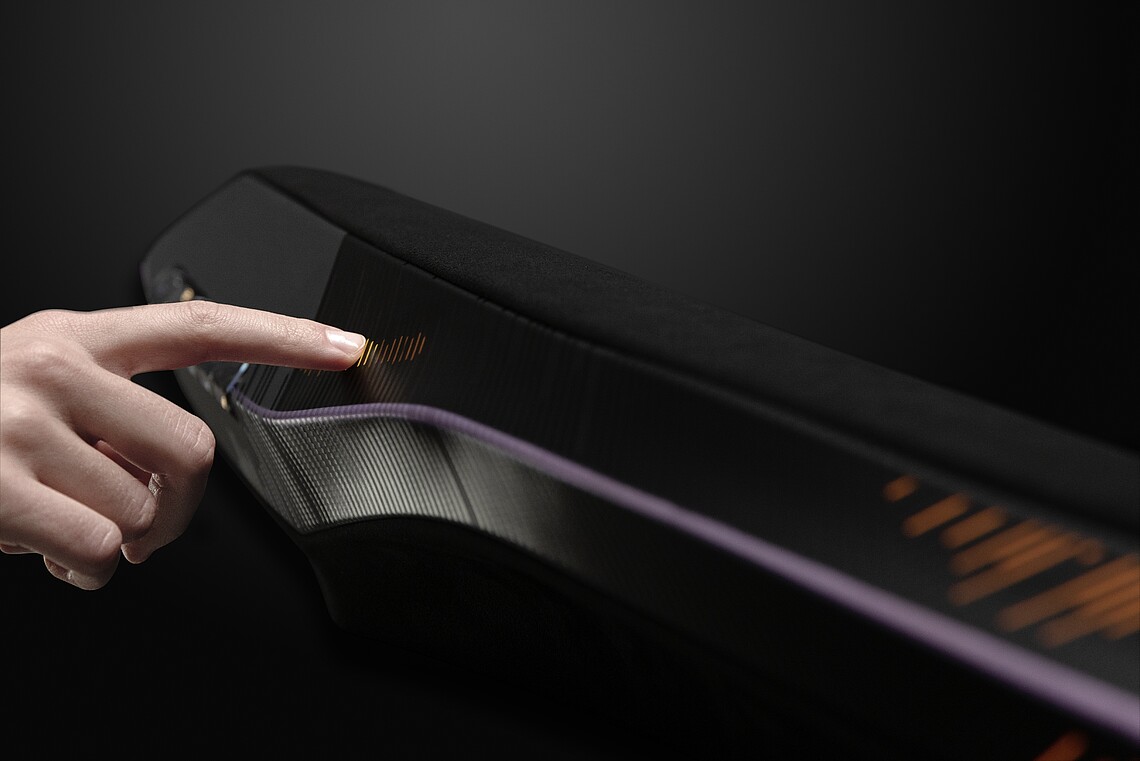

Functionality and design in just one injection molding process? Absolutely! KURZ and POLYIC combine In-Mold Decoration (IMD) and In-Mold Electronics (IME) in one operation. With the IMD/IME process, you not only benefit from innovative top-quality designs, but also from enormous cost advantages: no additional work steps or intermediate storage are required. In addition, the special PolyTC® films from POLYIC are conductive, flexible, wafer-thin, and even suitable for 3D geometries.

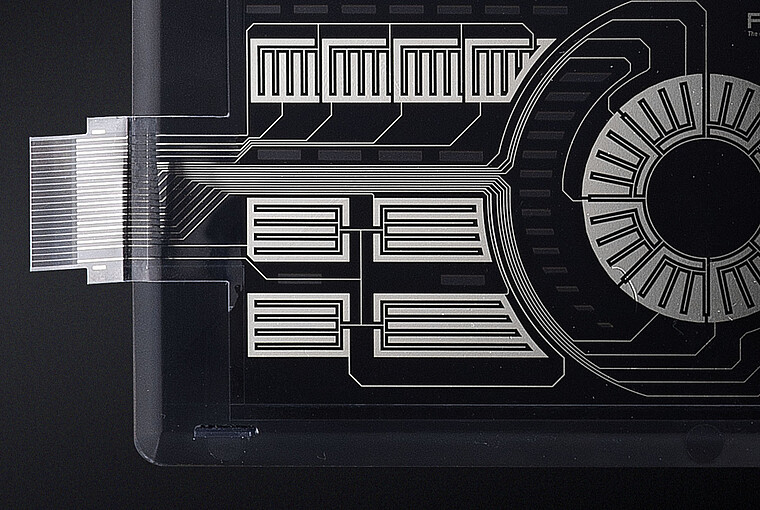

PolyTC® sensor films

PolyTC® sensor films are real all-rounders. Form and function are bridged by combining a high-resolution metal structure (metal mesh) with the transparent polyester substrate PET. Due to the grid-like arrangement of the silver microstructure, the sensor foils are extremely conductive and at the same time have the greatest possible mechanical flexibility. Whether it’s organically curved or bent 2D or 3D objects, cutting-edge modern design, or homogeneous dead-front surfaces, PolyTC® sensor films are versatile and easy to integrate into all plastic parts. Their robust character and high flexibility make them suitable for a wide variety of applications in coating and injection molding applications.

How much touch control do you fancy?

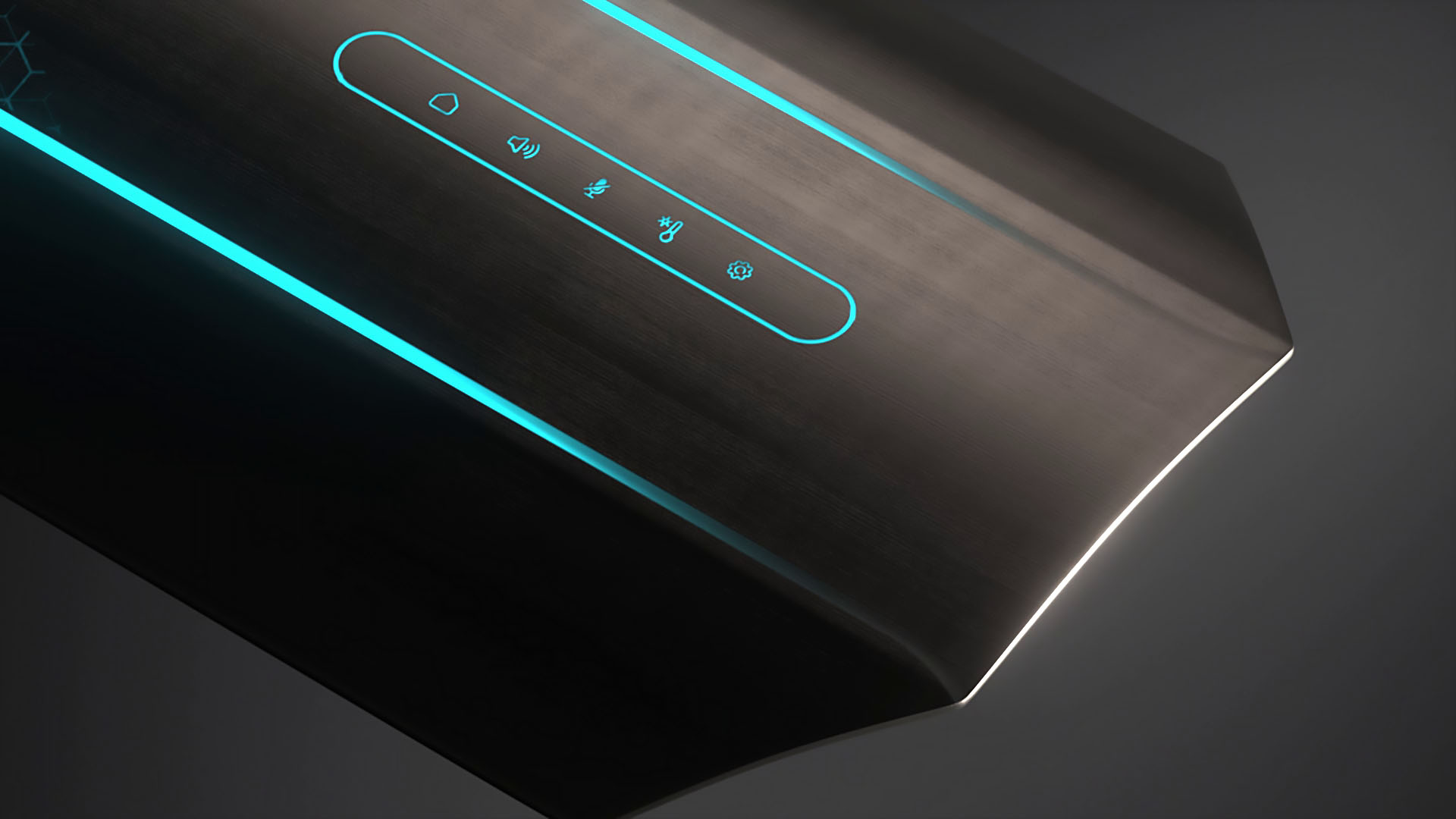

Whether display navigation via gesture control, single- or multi-touch, or with a tap on sensor keys: KURZ is reinventing Human-Machine Interface (HMI) concepts. The interface between man and machine meets the standards expected in terms of user experience and delivers premium functionality and innovative design. As the control elements are located behind the surface, homogenous and elegant designs can be produced, which are also more hygienic than conventional switches or controllers. They are very easy to clean, because there are no bumps in which dirt could accumulate. For components with touch functionality, KURZ offers maximum freedom of design: countless colors, patterns, and structures in deceptively real-looking marble, wood, or carbon effects are just as feasible as wide range of real metal coatings - indium-based metallization, bright metal colors, different gloss levels, or a brushed-metal look.

Touch control – the light makes the difference

Light is crucial for touch functionality. KURZ offers different design variations. For example, symbols on the surface are invisible and are only backlit with a swipe, a light tap or a circle of the finger (invisible until lit/deadfront). Another variant is the so-called day and night design: the surface displays different decors depending on the lighting conditions. Ambient lighting creates a special atmosphere. Freely selectable light colors, for example, design the interior of a car according to the driver's individual wishes. Abrasion resistance, durability or chemical resistance are just as much a matter of course as individual gloss levels or reflective properties. Talk to us. We make touch control suitable for your application.